Management of the logistics chain is a crucial challenge for companies, therefore it has become indispensable to acquire IT solutions so as to optimize one’s supply chain. Properly selected and paired with an ERP, these solutions enable optimal management of the entirety of the supply chain processes.

Supply Chain Management (SCM) solutions are used in managing the manufacturing of a product, starting with raw materials and through the various production and distribution processes. The objective of good management of the supply chain: reduce stocks while taking care to optimize the speed of routing of the product. In most cases, several companies are involved during a product’s life cycle, which makes optimizing flow management more complex. For a manager, properly targeting their needs remains of upmost importance in the selection of the right SCM solution. Some companies have activities requiring perfect management of the transportation of their goods, while others depend on their inventory management. This is why SCM solutions designers have created several types of software to respond to different needs.

One ambition, two solutions

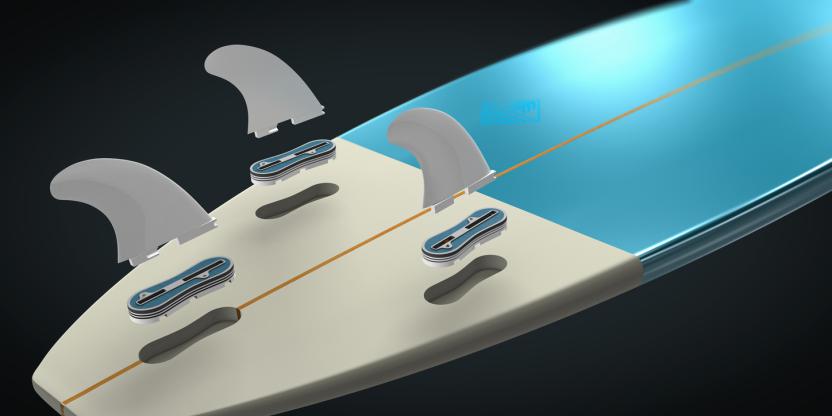

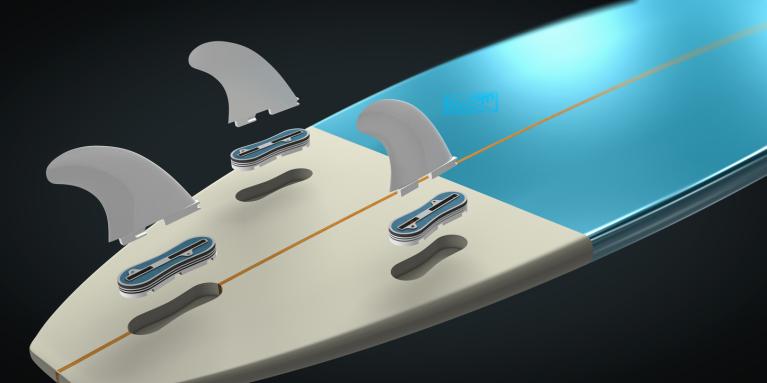

Corresponding to the optimization of routing and warehousing, the two main types of SCMs branch out in TMS (Transport Management System) for transport management, and in WMS (Warehouse Management System), for the management of warehouse processes.

To assist in planning, executing and optimizing the physical movement of goods, companies use TMS technology which provides management solutions at every stage of transport. It means having overview into day-to-day distribution operations, trade compliance information and documentation. So many moving parts to ensure the timely delivery of cargo and goods. Transportation management systems also streamline the shipping process and make it easier for companies to manage and optimize their routing operations, whether by land, air or sea. Many TMSs, specialized in different kinds of transportation, are available, thus the importance of selecting the most suitable solution.

If transportation optimization is often considered as the most complex task in logistics, warehouse management is just as important. The second group of logistical solutions is concerned with warehousing. In simple terms, WMS enables the optimizing of all warehouse processes. This is extremely important, not only because it follows all the products in the different warehouses of the company, but also because it can, likewise, create systems to streamline the way workers select the products and pack up the orders.

Given that the warehouse management system has access to all the data, a customer will immediately verify if the products are available when they place an order. So that a person does not manually cross the order and the inventory, the WMS will automatically label the order as ready to be packed. In fact, many WMS departments do self-finance when they are used in an effective manner.

Internal and external risks

Numerous risks inherent to the supply chain exist, this is why the choice of the logistics management solution is crucial. Among the internal risks: project management problems, difficulties related to human or physical resources, computing flaws or even planning errors.

Proper management of the supply chain allows to get ahead of external risks. Let’s mention sourcing difficulties, incorrect supplier relations management, the lack of traceability of their foreign currency payments, settlement and delivery delays or even quality control issues. Charles S. Tapiero, a researcher and professor at the New York University Polytechnic Institute, explains: “Generally speaking, SCM rests on an integration, collaboration and control policy minimizing the strategic risks, the power and information asymmetries.“ In other words, SCMs allow to limit these risks if they are well implemented and respond to the data needs of the collaborators at each link of the logistics chain.

Ever more advanced SCMs…

The great diversity of SCM solutions is an opportunity for supply chain managers who can select powerful tools to manage their logistics and avoid any flaws in the processes. Among the advantages of chain management software managing, one will note the possibility of automatically executing processes and therefore limiting errors. Applications track physical locations and the statuses of goods, the coordination of the required materials, and track financial data for all the involved parties. This means interfacing with various types of detection devices such as barcode scanners, radio frequency identification receivers and cameras. The cameras can interface with optical character recognition modules to read part labels in the inventory system. More advanced visual imaging systems can identify parts by their shape and dimensions, so that mislabeled parts can be examined and corrected. Artificial intelligence and Machine Learning are also revolutionizing supply chain management by integrating intelligent forecasting and self-learning functions into SCMs to optimize product delivery and storage performance as much as possible.

“The use of AI together with Machine Learning helps to create more accurate and efficient route planning. This automates system configuration, resulting in better operational results. Our customers are able to schedule delivery appointments and calculate their routing in real time. They also have better visibility over their fleet of vehicles,” states Sergio Torres, senior vice-president of Descartes, the foremost leading player in the supply chain management solutions software industry.

Demand Sensing: the new smart IKEA supply chain tool

IKEA has developed a forecasting tool based on statistical sales. This new tool includes, for instance, sales and demand models of the previous years, and make use of up to 200 data sources for each product so as to compute forecasts and determine future demand in a more efficient manner. The tool can use several influence factors, such as purchasing preferences during festivals, the influence of seasonal changes on consumer habits and weather forecasts, among others.

Peter Grimvall, IKEAs supply chain development head, explains: “Without appropriate and precise forecasting, we cannot understand demand: what needs to be delivered, to whom and at what time. Either demand is overestimated, and that increases our costs – and thus the price for our customers. Or it is underestimated, which implies we cannot propose them the right offer.” Now, by applying AI to supply chain planning, IKEA gives itself the means to manage well its activity by serving its customers in the best way possible.

… which increase in quality when coupled with an ERP

The data used by IKEA for their demand sensing forecasting tool are gathered on a worldwide scale in all of the brand’s stores. This is possible because the Swedish brand has an ERP gathering a multitude of data on the whole of its activities.

In a natural way and whatever the concerned industries may be, ERP and supply chain management go hand in hand. Supply chain management is a planning process of the way organizations supply components and materials on the entirety of the flow of goods or services so as to respond to demand commitments. The ERP plays an important role in the efficient management of the supply chain by managing the movement of merchandise within a company and by connecting the sources of supply and demand.

Today, supply chains are, more than ever, connected, evolutive and complex. The complexity, Edgar Morin, a sociologist and philosopher, describes it in these terms: “When I talk about complexity, I refer to what is woven together. The constituting parts are different, but one must see, just as in a tapestry, its entirety. The real problem, is that we have learned too well how to separate. It’s better to learn how to bind together.” And if the real issue for better managing the supply chain would be the best overall view, achieved by binding its links?

By Jonathan Lascaux, co-founder of FiveForty°

Sources :

ERP vs SCM: What are the key differences between these systems? | Omni

How ERPs Help Manufacturers With Their Supply Chain Management | Genius ERP

ERP or SCM: Making the Right Choice for Your Business | aACE

Supply Chain Management Software (SCM) Information | GlobalSpec

What Is A Warehouse Management System (WMS)? | Forbes

Using artificial intelligence for smarter demand forecasting | IKEA

L’innovation, une réponse à la complexité (Innovation, a response to complexity) | Centre Inffo

Analyse des risques et prise de décision dans la chaîne d'approvisionnement

(Supply chain risk analysis and decision taking) | Cairn.info

Descartes enrichit sa solution d'optimisation de tournées grâce à l’IA et au Machine Lear-ning

(Descartes enriches its delivery routing optimization solution thanks to AI and Machine Learning) | Faq logistique